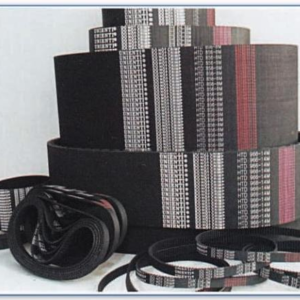

PU synchronous belt is made of thermoplastic polyurethane material, and the skeleton is made of steel wire or aramid wire, which ensures good performance, accurate and balanced transmission, and has the function of transmission and transmission.

Chemical properties

◆Chemical properties

◆Anti-aging, hydrolysis-resistant, UVA-resistant, ozone-releasing;

◆Working temperature -30て+80, can withstand up to +110C for a short period of time.

◆Highly oil and grease resistant.

◆ Resistant to most acid and alkali corrosion.

Machining performance

◆Dimensional stability ◆No maintenance required

◆ Low pretension ◆ Great elasticity

◆low noise ◆Linear speed up to 80 m/s

◆Highly resistant to wear ◆ High-precision linear positioning

PU synchronous belt can be processed and can be specially processed

◆Add cloth to sawtooth surface ◆Add cloth to the back of the belt

◆Cover the back with red glue ◆Add blocks to the back of the belt

Several applications of PU Synchronous Belt

1、PU Seamless belt

Each standard size synchronous belt is produced corresponding to a standard mold.The advantage is stable size and balanced standard width.

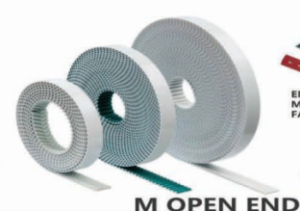

2、PU Open belt

It is continuously extruded by a fixed mold. The advantage is that the length can be specified arbitrarily, which solves the problem of long-distance transmission.

3、PU Connecting belt

PU connecting belt is a series of synchronous belts connected by openings. The connecting belts above 1 meter can be connected according to different sawtooth number requirements.

4、PU Flat belt

In addition to the characteristics of PU belts, PU flat belts also have high plane friction and can perform power transmission and transportation well.

评价

目前还没有评价